BLOG

2025 Top X-Ray Machines for Food Processing: Ensuring Safety and Quality

In the ever-evolving landscape of food processing, ensuring safety and quality is paramount. As we approach 2025, the importance of advanced technology, such as X-ray machines for food processing, becomes increasingly evident. Dr. Emily Carter, a leading expert in food safety technology, emphasizes the necessity of these machines by stating, "X-ray machines for food processing not only enhance the safety of our food supply but also improve overall operational efficiency."

The integration of X-ray technology in food processing facilities offers a robust solution to detect contaminants that may compromise food integrity. With stringent regulations and consumer demands for higher quality products, processors are turning to innovative equipment to meet these challenges head-on. The upcoming iteration of X-ray machines promises not just to meet compliance standards but to exceed them, ensuring that only the safest products reach consumers.

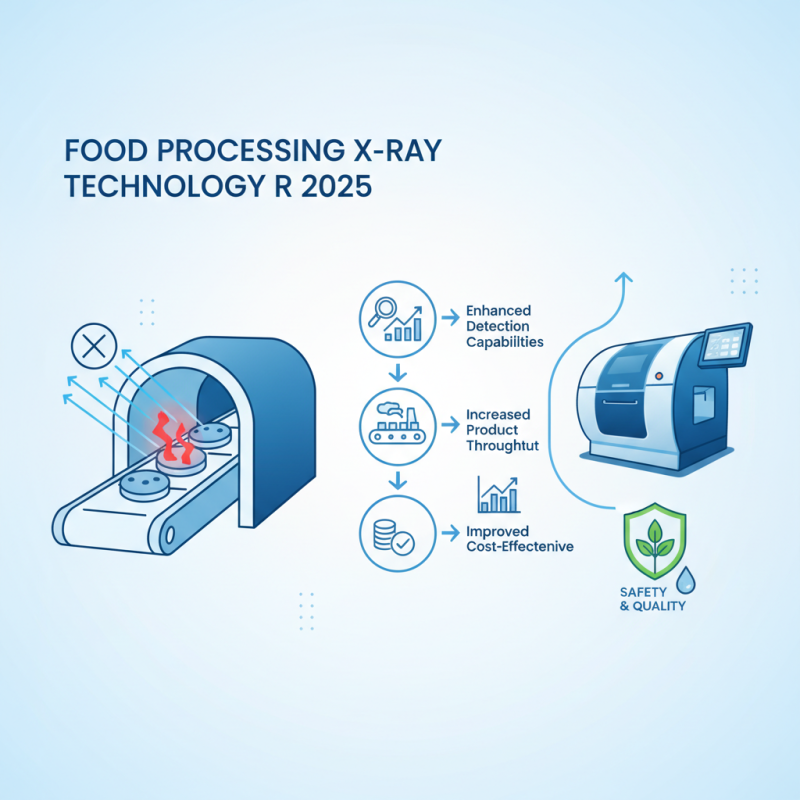

As we explore the top X-ray machines for food processing expected in 2025, it is essential to highlight the advancements that enhance detection capabilities, product throughput, and overall cost-effectiveness. The development of these machines will mark a significant leap forward in the food processing industry, ultimately transforming how safety and quality are maintained in the production process.

Advancements in X-Ray Technology for Food Safety in 2025

In 2025, the advancements in X-ray technology are set to revolutionize food safety standards across the processing industry. With an increasing demand for food safety and quality assurance, food manufacturers are adopting cutting-edge X-ray inspection systems to detect contaminants and ensure product integrity. According to a recent market analysis by Food Safety Insights, the global food X-ray inspection systems market is projected to grow by 12% annually, indicating a strong shift towards more sophisticated detection methods.

The latest X-ray machines employ high-resolution imaging and advanced artificial intelligence algorithms, allowing for real-time monitoring of food products. These innovations enable the identification of foreign objects, including metal, glass, and plastic contaminants, with unprecedented accuracy rates exceeding 99%. A report by the International Food Safety Association emphasizes that improved detection capabilities not only enhance product safety but significantly reduce recall rates, which affect millions of products each year. The integration of these technologies ensures compliance with stringent food safety regulations while minimizing risks to consumers.

In addition to contaminant detection, modern X-ray systems are also capable of assessing the integrity of packaging, ensuring that all products meet safety standards without compromising quality. As the food industry continues to evolve, the implementation of advanced X-ray technology is not just an option but a necessity for organizations committed to safeguarding food quality and consumer health.

2025 X-Ray Machines for Food Processing: Safety and Quality Analysis

This chart illustrates the percentage of food processing facilities adopting advanced X-ray machine technology across various sectors in 2025. The data reflects the growing emphasis on ensuring safety and quality in food products.

Key Features of Top X-Ray Machines for Food Processing

The food processing industry increasingly relies on advanced X-ray machines to ensure product safety and maintain quality control. Key features of top X-ray machines include high-resolution imaging capabilities, allowing for the detection of contamination or foreign bodies in food products with exceptional precision. According to a recent industry report by Mordor Intelligence, the global X-ray inspection market in food processing is projected to grow at a CAGR of over 7% from 2022 to 2027, underscoring the importance of adopting modern technology for food safety.

Another critical feature is real-time image processing, which enables operators to quickly identify potential hazards without halting production. The ability to integrate X-ray systems with data analytics further enhances efficiency, allowing for trend analysis and compliance tracking, which are vital in an industry facing stringent regulatory scrutiny. The data also reveal that 68% of food processors are investing in automation technologies like X-ray inspection systems to improve quality assurance and reduce the risk of recalls, ultimately protecting consumer health and brand integrity. As food safety becomes a priority, these advanced X-ray machines are becoming indispensable tools in the food processing landscape.

Benefits of X-Ray Inspection in Ensuring Food Quality

X-ray inspection has emerged as a pivotal technology in the food processing industry, playing a critical role in ensuring both safety and quality. By utilizing X-ray machines, food manufacturers can identify foreign contaminants, such as metal shards, glass fragments, and other unwanted materials that may compromise product integrity. This non-destructive method helps maintain high safety standards, enabling companies to deliver products that are not only safe to consume but also uphold the brand's reputation for quality.

Implementing X-ray inspection systems can offer numerous benefits beyond contaminant detection. They can assess product integrity by analyzing the packaging and ensuring that there are no defects that could lead to spoilage or contamination. Additionally, these systems can provide real-time data, allowing manufacturers to promptly address issues and maintain optimal production efficiency.

**Tips for Implementing X-Ray Inspection:**

- Regularly calibrate your X-ray machines to ensure accuracy and reliability in detecting contaminants.

- Train your staff on the operation and maintenance of X-ray technology to maximize its effectiveness.

- Conduct routine audits of your x-ray inspection process to identify any areas for improvement and ensure compliance with quality standards.

Comparative Analysis of Leading X-Ray Machine Brands

In the food processing industry, maintaining safety and quality standards is paramount. A comparative analysis of leading X-ray machine brands reveals significant variations in their technology, efficiency, and application suitability. According to a report by the Food and Drug Administration (FDA), the integration of X-ray inspection systems has increased by over 35% in the last decade, emphasizing their importance in detecting contaminants such as metal, glass, and stones, which can pose serious health risks. Advanced models now incorporate automated image analysis, which not only speeds up inspections but also enhances detection accuracy.

When selecting an X-ray machine, consider factors such as sensitivity, throughput, and ease of use. Important metrics include the ability to consistently detect foreign objects smaller than 1 mm and a processing speed of at least 100 products per minute. Efficiency is critical; manufacturers are encouraged to opt for machines that can seamlessly integrate into existing production lines with minimal disruption.

Tip: Regular maintenance of X-ray machines is vital for optimal performance. Implement a routine calibration schedule to ensure consistent accuracy and reliability in detection, preventing costly product recalls and ensuring compliance with safety regulations. Moreover, training staff on proper use and maintenance of these machines can further enhance productivity and safety. Another important aspect to consider is the machine's ability to adapt to varying product types, as the versatility can provide a significant advantage in a dynamic processing environment.

Regulatory Standards and Compliance in Food Processing X-Ray Use

In the food processing industry, ensuring safety and quality through effective X-ray technology has become paramount. Regulatory standards and compliance play a crucial role in governing the use of X-ray machines in this sector. The U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA) set forth guidelines to ensure that X-ray systems are used safely while preventing contamination and ensuring food safety. According to the FDA, food products must be free from physical hazards, which is where X-ray technology proves essential in detection and quality assurance.

Recent industry reports indicate a growing trend towards the adoption of X-ray technology in food processing settings, with a projected market growth of over 5% annually through 2025. These machines are meticulously designed to comply with safety standards that limit radiation exposure to negligible levels. Regulatory compliance not only safeguards the consumers’ health but also fortifies the manufacturers’ reputations. The alignment with both local and international regulatory frameworks ensures that food producers can maximize operational efficiency while consistently delivering safe and high-quality products to the market.

2025 Top X-Ray Machines for Food Processing: Ensuring Safety and Quality

| Machine Model | Detection Sensitivity | Image Resolution | Regulatory Compliance | Applications |

|---|---|---|---|---|

| XRM-2025A | 0.25 mm | 1024 x 768 pixels | FDA, CE | Meat, Dairy |

| XRM-2025B | 0.20 mm | 1280 x 1024 pixels | USDA, ISO | Bakery, Snacks |

| XRM-2025C | 0.15 mm | 1920 x 1080 pixels | FDA, HACCP | Fruits, Vegetables |

| XRM-2025D | 0.10 mm | 2560 x 1440 pixels | CE, ISO | Canned Goods, Seafood |

Related Posts

-

Top 7 Benefits of Using X Ray Machines for Food Processing Efficiency

-

2025 How to Utilize Xray Inspection Technology for Enhanced Quality Control in Manufacturing

-

How to Use Xray Inspection for Effective Quality Control in Manufacturing

-

Top 5 Food Inspection Systems Revolutionizing Quality Control in the Industry

-

How to Use Metal Detectors Safely in the Pharmaceutical Industry

-

How to Choose the Right X Ray Machine for the Food Industry