BLOG

Top 10 Benefits of Using Varpe Checkweighers in Manufacturing Processes

In the fast-paced world of manufacturing, accuracy is crucial. The varpe checkweigher stands out as an essential tool. It ensures that products meet weight specifications. This can reduce waste, enhance efficiency, and improve overall quality. Many manufacturers have experienced the benefits firsthand.

Using a varpe checkweigher can streamline production lines. It minimizes human error and increases reliability. With real-time weight monitoring, adjustments can be made instantly. This feature not only boosts productivity but also helps maintain consistency. However, integrating such technology requires careful consideration. Training staff is vital for maximizing its potential.

Some may overlook the importance of these devices. They might see them as just another expense. This viewpoint neglects the long-term advantages that a varpe checkweigher can offer. It provides valuable data, allowing manufacturers to refine their processes. Embracing this technology could very well determine future success.

The Role of Varpe Checkweighers in Enhancing Manufacturing Efficiency

In modern manufacturing, efficiency is crucial.

Checkweighers play a vital role in this process.

They ensure that products meet weight specifications. According to industry reports, implementing checkweighers can reduce overall production errors by up to 25%.

This significant improvement directly impacts profitability.

Accurate weight measurements are essential. Inaccurate weights can lead to financial loss and customer dissatisfaction.

An estimated 3% of products are rejected at retail due to weight discrepancies. This is a stark reminder of the importance of precision.

With checkweighers, manufacturers can minimize waste and rework, enhancing operational efficiency.

However, some facilities may overlook the integration of checkweighers.

They might hesitate due to initial costs or perceived complexity. This can be a mistake.

The long-term benefits often outweigh upfront expenses. Companies could miss opportunities for efficiency improvements that streamline their operations.

A balanced approach to adopting this technology is crucial for sustained performance.

Improved Accuracy and Precision in Product Weight Measurement

In the manufacturing sector, accuracy in product weight measurement is crucial. A recent industry report highlighted that inaccurate weight assessments lead to overproduction and financial losses. Checkweighers can mitigate these issues effectively. These machines deliver weights with an accuracy of up to ±0.1 grams, significantly reducing the risk of underfilling or overfilling products.

Moreover, implementing checkweighers improves precision across packaging lines. This technology can instantly detect weight discrepancies and alert operators. For instance, studies show that companies using checkweighers saw a 30% decrease in product recalls related to incorrect weights. However, it's important to recognize that not all checkweighers are created equal. Some may require frequent calibration, which can disrupt production schedules and lead to downtime.

The integration of checkweighers can also streamline compliance with industry regulations. A whopping 55% of manufacturers faced fines due to weight inaccuracies last year. Automated systems provide real-time data tracking, enabling manufacturers to adjust processes swiftly. Still, relying solely on technology isn't foolproof. Regular inspections and maintenance are necessary to ensure the effectiveness of these machines. This balance between automation and human oversight is key to achieving optimal accuracy in weight measurement.

Reduction of Waste and Cost Savings in Production Lines

In modern manufacturing, waste reduction is key to success. Varpe checkweighers provide a solution to minimize excess materials. By accurately measuring product weights on production lines, manufacturers can identify discrepancies early. This process saves resources and cuts costs associated with overproducing items or reworking faulty ones.

To enhance the effectiveness of checkweighers, invest in staff training. Ensure your team understands how to interpret the data. This helps optimize the use of materials and boosts overall productivity. Implement regular checks on equipment calibration. An uncalibrated machine can lead to significant losses.

It's crucial to analyze weight data regularly. Use this information to spot trends in production. Allowing for adjustments will help maintain consistency. While errors may occur, learning from these mistakes leads to improvement. A flexible approach will enable the production line to respond swiftly to changing demands.

Top 10 Benefits of Using Varpe Checkweighers in Manufacturing Processes - Reduction of Waste and Cost Savings in Production Lines

| Benefit | Description | Estimated Cost Savings (%) |

|---|---|---|

| Waste Reduction | Minimizes excess product by ensuring accurate weight measurements. | 10% |

| Enhanced Accuracy | Increases accuracy in product weight, leading to less rework. | 8% |

| Better Compliance | Ensures adherence to legal and quality standards in packaging. | 6% |

| Reduced Labor Costs | Automated checkweighing reduces the need for manual inspections. | 15% |

| Increased Efficiency | Speeds up the production line by reducing delays caused by weight checks. | 12% |

| Data Collection | Provides valuable data for process optimization and tracking. | 5% |

| Product Consistency | Maintains uniform product weight, improving customer satisfaction. | 7% |

| Improved Profitability | Lower production costs contribute to higher profit margins. | 18% |

| Ease of Integration | Easily integrates with existing production line systems. | 3% |

| Customer Trust | Consistent product weight builds customer loyalty and trust. | 4% |

Integration of Checkweighers with Existing Manufacturing Systems

Integrating checkweighers into existing manufacturing systems can significantly enhance efficiency and accuracy. A recent report from a manufacturing analysis group indicates that improper weight measurements can lead to a loss of up to 5% in product yield. This not only wastes resources but also affects overall production costs. Checkweighers serve as an essential tool in minimizing these inaccuracies, ensuring that each item meets required specifications before packaging.

Moreover, implementing checkweighers within production lines presents unique challenges. While the technology is sophisticated, it requires skilled personnel for setup and calibration. Training teams to use checkweighers effectively can take time. A study by industry experts revealed that 30% of operators struggle with initial integration. This learning curve can temporarily disrupt production flow. Despite these challenges, the long-term benefits greatly outweigh these initial hurdles.

Furthermore, checkweighers can seamlessly connect with existing data systems, providing real-time feedback. This integration helps identify variations in weight trends that could indicate larger issues, such as equipment malfunctions. However, relying solely on automation without human oversight presents risks. Even with state-of-the-art systems, a human touch is necessary for decision-making. Therefore, striking a balance between automation and human intervention is crucial.

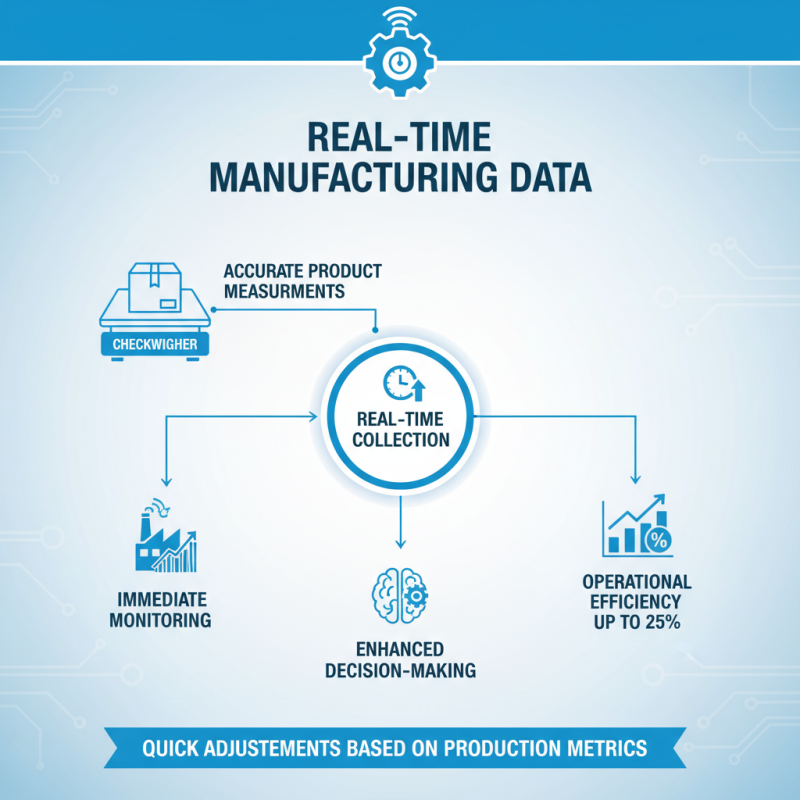

Real-Time Data Collection and Analysis for Informed Decision Making

In today's manufacturing landscape, real-time data collection is crucial. Checkweighers provide accurate measurements of products, enabling manufacturers to monitor weight immediately. This integration of checkweighers helps to enhance the decision-making process significantly. According to industry studies, real-time data analysis boosts operational efficiency by up to 25%. It allows for quick adjustments based on current production metrics.

Collecting data in real-time can also minimize waste. When discrepancies in weight are detected early, products can be corrected or rejected before finishing the line. This proactive approach saves costs associated with overpackaging or underfilled items. However, some companies still underestimate the importance of this technology. Investing in checkweighers can seem overwhelming at first, yet the long-term benefits often outweigh initial costs.

Tips: Regularly review the data collected during production. This practice can reveal patterns or issues that might not be immediately visible. Training staff on how to interpret data is equally important. Empowering team members ensures they can make timely decisions based on collected insights. Each of these steps contributes to refining manufacturing processes and ensuring product quality.

Related Posts

-

Why Metal Detectors Are Essential for Quality Control in the Pharmaceutical Industry

-

Why Food X-Ray Technology is Revolutionizing Food Safety and Inspection?

-

Top X-Ray Inspection Systems: How They Enhance Safety and Efficiency

-

Top 10 Factors Influencing Food X-Ray Machine Prices You Must Know

-

Why a Varpe Checkweigher is Essential for Your Production Line Efficiency

-

Top 5 Food Inspection Systems Revolutionizing Quality Control in the Industry