BLOG

Why Metal Detectors Are Essential for Quality Control in the Pharmaceutical Industry

The pharmaceutical industry is characterized by stringent quality control measures, as the safety and efficacy of medications are paramount. In order to maintain these standards, metal detectors have become an essential tool within production environments. According to a report from the pharmaceutical quality assurance sector, contamination with metal fragments can lead to significant financial losses, legal ramifications, and damage to company reputations. Statistics indicate that up to 70% of recalls in the pharmaceutical market can be attributed to contamination, emphasizing the critical role that a metal detector in pharmaceutical industry can play in preventing such incidents.

Implementing metal detection systems not only enhances product safety but also ensures compliance with regulatory bodies such as the FDA and EMA. These organizations mandate that pharmaceutical manufacturers adopt measures to identify and eliminate foreign substances during production processes. With advancements in technology, modern metal detectors are now capable of detecting even the smallest metal fragments across various products, thereby increasing operational efficiency and safeguarding both consumer health and corporate integrity. This introduction underscores the necessity of investing in reliable metal detection solutions to uphold the principles of quality control and maintain high safety standards within the pharmaceutical industry.

Importance of Quality Control in the Pharmaceutical Industry

Quality control is a critical aspect of the pharmaceutical industry, serving as a safeguard to ensure that products meet the stringent standards required for safety, efficacy, and quality. With the increasing complexity of pharmaceutical manufacturing processes, implementing robust quality control measures has never been more essential. This involves a systematic approach to testing and evaluating substances at every stage of production, from raw materials to finished products, ensuring that any contaminants or deviations from prescribed standards are identified and addressed promptly.

Among the many tools used in quality control, metal detectors play a crucial role in the detection of foreign contaminants. These devices are essential in protecting consumers from potentially harmful substances that could compromise the integrity of pharmaceutical products. By identifying metallic impurities during production, companies not only comply with regulatory requirements but also uphold their commitment to patient safety. In an industry where trust is paramount, the implementation of effective quality control measures, including the use of metal detectors, reinforces the assurance that products are safe and reliable, ultimately enhancing the public's confidence in pharmaceutical offerings.

Role of Contaminants in Pharmaceutical Products

Contaminants in pharmaceutical products pose significant risks to both consumer safety and product efficacy. According to the U.S. Food and Drug Administration (FDA), foreign material contamination is a leading cause of product recalls, with the agency reporting that approximately 25% of drug recalls are due to contamination issues. These contaminants can arise from various sources, including raw materials, manufacturing processes, and even packaging. As such, maintaining stringent quality control measures is crucial in safeguarding the integrity of pharmaceutical products.

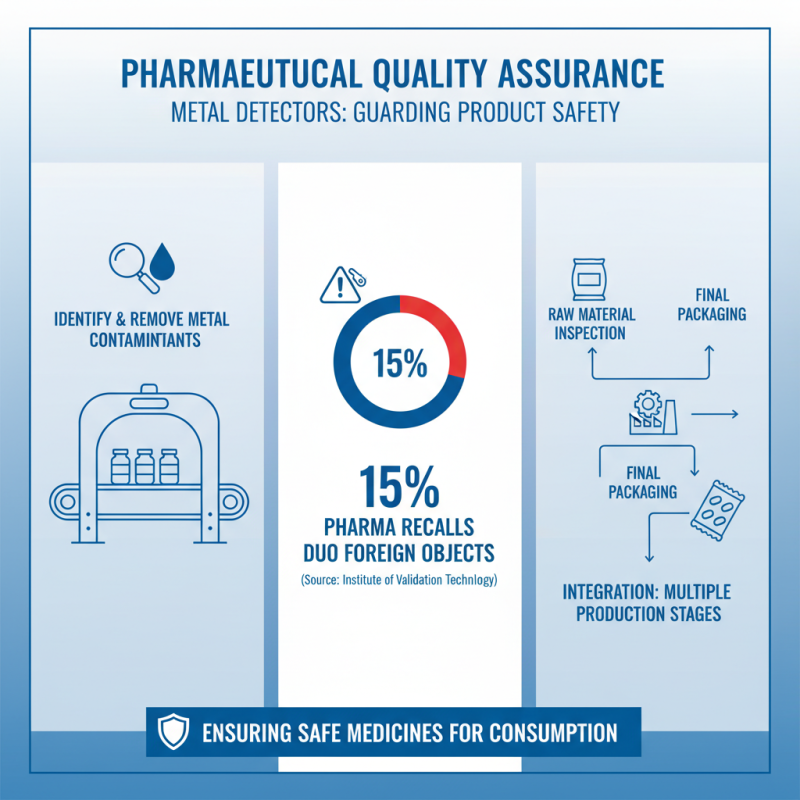

The presence of metal contaminants is particularly concerning as even minute quantities can cause serious health issues or negatively impact the therapeutic effectiveness of medications. A report by the International Society for Pharmaceutical Engineering (ISPE) noted that metal fragments have been detected in over 15% of pharmaceutical products undergoing routine inspections, underscoring the importance of early detection systems such as metal detectors. These devices play a pivotal role in quality control, enabling manufacturers to identify and eliminate contaminants before products reach the market, thus ensuring compliance with regulatory standards and safeguarding patient health. With the escalating complexity of pharmaceutical processes and materials, the implementation of metal detection technology has transitioned from being a mere precaution to an essential component of quality assurance programs within the industry.

Functionality of Metal Detectors in Pharmaceutical Quality Assurance

Metal detectors play a crucial role in ensuring quality assurance within the pharmaceutical industry. Their primary functionality revolves around identifying and removing metal contaminants that could compromise product safety. According to a report by the Institute of Validation Technology, up to 15% of recalls in the pharmaceutical sector are caused by foreign objects, including metal debris. This significant statistic underscores the importance of integrating metal detection systems at various stages of production, from raw material inspection to the final packaging process, ensuring that medicines are safe for consumption.

Implementing metal detectors not only protects consumers but also enhances compliance with regulatory standards set by authorities like the FDA and EMA. These agencies mandate rigorous quality assurance protocols, where metal detection systems are key components of a hazard analysis and critical control point (HACCP) plan. By accurately detecting ferrous and non-ferrous metals, these devices help pharmaceutical companies mitigate risks and avoid costly recalls and legal penalties.

Tips: Regularly calibrate metal detection equipment to maintain accuracy and effectiveness. Ensure that employees are trained in the operation and maintenance of these systems to maximize their potential in quality control. Additionally, documenting detection rates and incidents can provide valuable data for continuous improvement in manufacturing processes.

Benefits of Implementing Metal Detection Systems

Implementing metal detection systems in the pharmaceutical industry is crucial for ensuring product safety and maintaining quality control standards. These systems effectively identify and remove metallic contaminants that can compromise the integrity of pharmaceuticals, from raw materials to finished products. By preventing contaminated products from reaching consumers, companies can enhance their reputation and reduce the risk of costly recalls.

One significant benefit of these systems is their ability to streamline quality assurance processes. Metal detectors automatically inspect products during various stages of production, allowing for consistent monitoring without the need for labor-intensive manual checks. This not only saves time but also increases efficiency, enabling companies to focus resources on other critical quality control measures.

**Tips for Implementing Metal Detection Systems:**

1. Assess the specific needs of your production line to choose the most suitable metal detector type and sensitivity level.

2. Regularly calibrate and maintain detection systems to ensure accurate performance and address any potential sensor drift.

3. Train staff thoroughly on operating detection systems and establishing protocols for handling identified contaminants to maintain high safety standards.

Why Metal Detectors Are Essential for Quality Control in the Pharmaceutical Industry - Benefits of Implementing Metal Detection Systems

| Parameter | Description | Impact |

|---|---|---|

| Detection Sensitivity | Ability to detect small metal contaminants | Enhances product safety and reduces risk of recalls |

| Regulatory Compliance | Meets FDA and GMP regulations for product safety | Ensures legal compliance and avoids penalties |

| Cost Reduction | Prevents product recalls and legal issues | Saves potential costs associated with safety violations |

| Consumer Trust | Ensures high-quality standards in products | Builds brand reputation and customer loyalty |

| Operational Efficiency | Automation of inspection processes | Improves productivity and reduces manual checks |

Regulatory Standards for Metal Detection in Pharmaceuticals

In the pharmaceutical industry, regulatory standards for metal detection are paramount to ensuring product safety and compliance. Authorities such as the FDA and EMA mandate rigorous testing for contaminants, including metal fragments, in pharmaceutical products. These regulations aim to protect consumers from harmful substances that could cause adverse health effects. As a result, manufacturers are required to implement robust metal detection systems during the production process to meet these standards.

Metal detection not only helps in adhering to regulatory requirements but also enhances the quality assurance process within pharmaceutical manufacturing. Companies are expected to conduct routine checks and maintenance on detection equipment to ensure optimal performance. Failure to comply with these regulations can lead to severe penalties, including product recalls and reputational damage. Therefore, integrating reliable metal detection technology is essential not just for regulatory compliance, but also for maintaining the integrity and safety of pharmaceutical products.

Why Metal Detectors Are Essential for Quality Control in the Pharmaceutical Industry

This chart shows the detection rates of various metals that are essential for quality control in the pharmaceutical industry. Maintaining high detection rates is crucial to comply with regulatory standards and ensure product safety.

Related Posts

-

How to Use Metal Detectors Safely in the Pharmaceutical Industry

-

2025 How to Utilize Xray Inspection Technology for Enhanced Quality Control in Manufacturing

-

Top 5 Food Inspection Systems Revolutionizing Quality Control in the Industry

-

How to Use Food X-Ray Technology for Safer and Healthier Eating Choices

-

What is Food Xray and How It Revolutionizes Food Safety with Industry Insights and Data

-

How to Effectively Use X-Ray Inspection for Quality Control in Manufacturing