BLOG

What is X Ray Food Inspection Systems and How Do They Work?

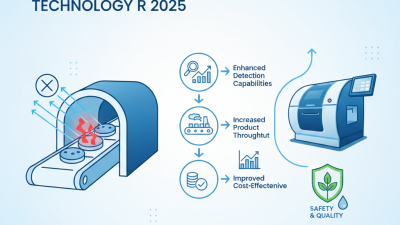

In the food industry, safety and quality are paramount. X ray food inspection systems play a crucial role in ensuring these standards. They help detect contaminants and foreign objects in food products. According to industry reports, the global food inspection market is expected to reach USD 20 billion by 2025, showcasing the rising emphasis on food safety.

X ray technology has transformed inspection processes. These systems can identify metal, glass, and plastic contaminants effectively. More importantly, they enable manufacturers to verify the integrity of packaging. A report from the Food Safety and Inspection Service indicates that improper inspection can lead to contamination outbreaks. Considering this, adopting x ray food inspection systems is a proactive step.

However, reliance on technology can have drawbacks. Some contaminants can still escape detection, leading to potential health risks. It's essential for food manufacturers to regularly evaluate their inspection processes. While x ray food inspection systems are effective, they are not infallible. Continuous improvement and vigilance remain critical in food safety practices.

Understanding X Ray Food Inspection Systems

X-ray food inspection systems are crucial in food safety. They use advanced technology to analyze products for contaminants. This method helps ensure that food reaching consumers is safe to eat. X-rays penetrate packaging and create images of the contents inside. These images reveal foreign objects, density variances, and even irregularities in product structure.

When using an X-ray inspection system, it’s essential to calibrate the machine properly. Calibration affects accuracy. Operators should receive training to understand the nuances of the equipment. Familiarity with machine settings leads to better results. Inspect the products regularly. A consistent inspection routine helps catch issues early on.

Tips: Always clean the X-ray machine after use. Residue can interfere with analysis. Schedule regular maintenance checks to ensure optimal performance. Stay updated with the latest technology and adjust techniques as necessary. Remember, understanding your equipment is key to effective inspections.

The Technology Behind X Ray Food Inspection

X-ray food inspection systems employ advanced technology to ensure food safety. These systems use

X-ray radiation to scan food products as they pass through a conveyor belt. The radiation penetrates the food and produces a

detailed image of its internal structure. This helps identify foreign objects like

metal, glass, or

plastic that may have inadvertently made it into the food.

The technology is fascinating. X-rays are safe when controlled properly. However, there remains a concern about potential exposure to radiation. Food inspectors must be trained to operate these systems effectively. They require a good understanding of how to interpret the images generated. Occasionally, the accuracy can be hindered by the type of food being scanned.

Dense items can obscure the view, leading to false negatives.

Despite advancements, the systems are not flawless. There are instances where the detection rate can fall short. Some small contaminants might evade detection. Regular calibration and maintenance of the machines are crucial. It's important to reassess protocols frequently to enhance efficacy. Continuous improvement in the technology can bring better accuracy and reliability.

How X Ray Food Inspection Systems Function

X-ray food inspection systems are crucial in ensuring food safety. They utilize advanced imaging technology to detect contaminants in packaged foods. These systems create images of the products, allowing inspectors to identify foreign objects such as metal, glass, or plastic that may pose health risks.

Research indicates that over 80% of food recalls are due to contaminants. This highlights the importance of X-ray systems in food processing. The technology operates by directing X-ray beams through the product. The denser the material, the more radiation it absorbs. This creates a contrast on the device's screen, making it easy to spot anomalies.

However, there are challenges. Misinterpretations can occur if the operator lacks proper training. Additionally, some products might contain naturally occurring foreign materials that confuse detection systems. Industry reports suggest continuous training can reduce false positives. Implementing stricter protocols is essential for maintaining food safety. Overall, the effectiveness of X-ray systems hinges on both technology and human expertise.

Benefits of Using X Ray Inspection in the Food Industry

X-ray food inspection systems play a crucial role in enhancing food safety. They detect foreign objects, contaminants, and defects in food products. According to a recent industry report, nearly 90% of food safety professionals believe that these systems reduce the risk of food recalls. Contaminants include metals, glass, and plastic. Eliminating these risks saves manufacturers millions in potential losses.

The benefits of using X-ray inspection in the food industry are significant. It not only improves product quality but also boosts consumer confidence. A study shows that 70% of consumers are more likely to trust brands that prioritize safety measures. However, implementing such technology can be challenging. High initial costs and the need for regular calibration are common concerns. Food companies must weigh the pros and cons before making a decision.

Quality assurance is vital. X-ray systems provide real-time feedback during production. This helps in maintaining consistent standards. Yet, there can be false positives. This leads to unnecessary rejections or product waste. The balance between efficiency and accuracy requires continuous evaluation. Investing in training can improve the effectiveness of these systems.

Challenges and Limitations of X Ray Food Inspection Systems

X-ray food inspection systems offer advanced techniques to ensure food safety. However, they come with notable challenges. One significant limitation is the high initial cost of these systems. Many small to medium-sized enterprises struggle to justify such an investment. According to industry reports, 70% of food processors hesitate to adopt these technologies due to budget constraints.

The technology also faces operational challenges. X-ray systems require regular maintenance and calibration to function effectively. If not properly maintained, accuracy can decline, resulting in potential false positives or negatives. Industry studies show that around 30% of users reported issues with detection sensitivity, which could lead to undetected contaminants.

Training staff to operate these systems effectively presents another hurdle. The complexity of data interpretation and system management may overwhelm employees. A survey revealed that nearly 50% of food safety professionals feel inadequately trained in X-ray technology. This gap creates a risk of mismanagement, further complicating food safety efforts in the industry.

Related Posts

-

2025 Top X-Ray Machines for Food Processing: Ensuring Safety and Quality

-

Top 10 Tips for Effective X Ray Food Inspection Systems to Ensure Safety

-

Top X-Ray Inspection Systems: How They Enhance Safety and Efficiency

-

Top 10 Food X-Ray Machine Prices and Insights for 2023: A Comprehensive Guide

-

Top 10 Factors Influencing Food X-Ray Machine Prices You Must Know

-

2026 Best X Ray Food Inspection Technologies and Innovations?