BLOG

Top X-Ray Inspection Systems: How They Enhance Safety and Efficiency

In the ever-evolving landscape of quality control and safety regulations, X-ray inspection systems have become indispensable across various industries. According to a report from the International Journal of Advanced Manufacturing Technology, the global market for X-ray inspection systems is projected to grow at a CAGR of 5.6% over the next five years, reflecting the increasing recognition of their role in enhancing operational safety and efficiency. These systems not only streamline the inspection process but also minimize human error, ensuring that products meet stringent quality standards.

As highlighted by industry expert Dr. Emily Stone, a leading authority in non-destructive testing technologies, “The integration of X-ray inspection systems is transforming how industries approach their quality assurance protocols. They not only speed up the inspection process but also offer unparalleled accuracy in detecting defects.” This statement underscores the critical role that X-ray technology plays in enhancing safety measures and operational efficiency, making it a key component in sectors ranging from manufacturing to pharmaceuticals. As organizations continue to prioritize safety and quality, investing in advanced X-ray inspection systems will undoubtedly remain a pivotal strategy in maintaining competitiveness in a rapidly changing market.

Overview of X-Ray Inspection Systems in Various Industries

X-ray inspection systems play a crucial role across various industries by enhancing safety and efficiency through detailed analysis of materials and components. In the aerospace sector, for instance, these systems are instrumental in ensuring the structural integrity of aircraft parts. According to a report by the Aerospace Industries Association, the use of X-ray technology has led to a 35% reduction in the failure rate of critical components, significantly improving safety standards in air travel. This level of precision not only safeguards passengers but also cuts down costs associated with maintenance and repairs.

In the food industry, X-ray inspection systems are increasingly adopted for quality control and contamination detection. A report from the Food and Drug Administration highlights that inspections using X-ray technology can detect foreign objects effectively, achieving a detection rate exceeding 95%. This capability ensures that food products are safe for consumption, thereby enhancing consumer trust and compliance with stringent safety regulations. As industries continue to embrace advanced inspection technologies, the reliance on X-ray systems for ensuring product quality and safety is set to grow, contributing to overall operational efficiencies.

Top X-Ray Inspection Systems: How They Enhance Safety and Efficiency

| Industry | X-Ray Technology Type | Application | Benefits | Efficiency Improvement |

|---|---|---|---|---|

| Manufacturing | Computed Tomography (CT) | Defect detection in electronic components | Reduces failure rates | 30% faster inspections |

| Healthcare | Digital Radiography | Patient diagnostics | Improved image quality | 20% reduction in time |

| Aerospace | X-Ray Fluoroscopy | Weld integrity inspection | Increased safety | 25% faster inspections |

| Food Processing | X-Ray Detection Systems | Foreign object detection | Enhanced product safety | 40% more efficient |

| Logistics | X-Ray Scanning Systems | Cargo screening | Improved security | 50% reduction in inspection time |

Key Features and Technologies of Modern X-Ray Inspection Systems

Modern X-ray inspection systems have revolutionized safety and efficiency across various industries, from manufacturing to food safety. One of the key features that enhance their effectiveness is the integration of advanced imaging technologies. For instance, the use of dual-energy X-ray technology allows for better material differentiation, enabling systems to distinguish between various substances based on their atomic density. According to a recent report by the International Journal of Advanced Manufacturing Technology, companies that adopt these systems experience a reduction in false positives by up to 30%, significantly improving operational efficiency.

Additionally, modern X-ray systems are equipped with sophisticated software algorithms that enhance image analysis capabilities. These algorithms not only improve defect detection but also streamline decision-making processes. For example, artificial intelligence-driven systems can learn from previous inspection data, enabling continuous improvement in detection rates. A study published by MarketsandMarkets indicates that the market for AI in industrial applications is projected to reach $16 billion by 2025, underscoring the growing reliance on automated inspection technologies. This trend highlights the potential for increased safety and reduced downtime across sectors, ensuring that products meet stringent quality standards while maximizing operational output.

Benefits of X-Ray Inspection Systems for Safety and Efficiency

X-ray inspection systems play a crucial role in various industries by enhancing safety and operational efficiency. These systems utilize advanced imaging technology to detect abnormalities and potential hazards in both goods and infrastructure. One of the primary benefits is their ability to identify issues that are not visible to the naked eye. This capability significantly reduces the risk of accidents and ensures that products meet safety standards before distribution. By implementing X-ray inspection processes, companies can mitigate liabilities and improve the overall safety of their operations.

Moreover, the efficiency offered by X-ray inspection systems translates into streamlined workflows and reduced downtime. Traditional inspection methods can be time-consuming and often lead to bottlenecks in production. In contrast, X-ray systems provide rapid and accurate results, allowing for faster decision-making and maintenance procedures. This not only enhances productivity but also fosters a proactive approach to safety management. Regular inspections help in identifying wear and tear before it escalates into larger issues, thereby increasing the longevity of equipment and reducing replacement costs. Overall, the integration of X-ray inspection technology is a forward-thinking solution that bolsters both safety and efficiency in various sectors.

Top X-Ray Inspection Systems: Enhancing Safety and Efficiency

The chart above illustrates the key benefits of X-Ray Inspection Systems in terms of enhancing safety and operational efficiency. Each bar represents the level of improvement observed across different dimensions, showcasing the importance of investing in advanced inspection technologies.

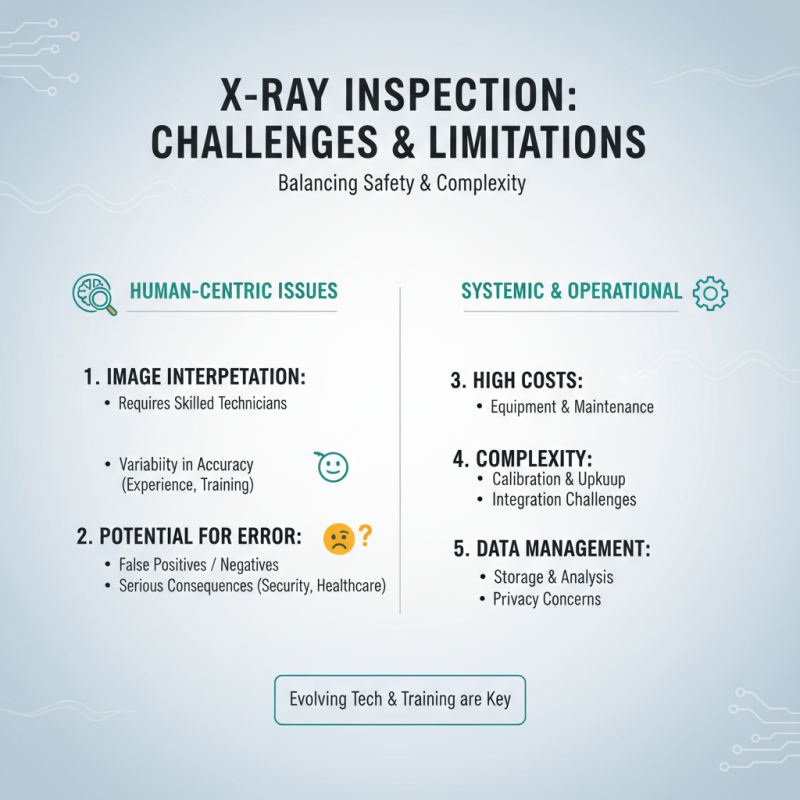

Challenges and Limitations of X-Ray Inspection Technologies

While X-ray inspection systems significantly enhance safety and efficiency in various industries, they also come with several challenges and limitations that must be acknowledged. One major challenge is the interpretation of X-ray images. Skilled technicians are required to correctly analyze and diagnose the images generated by these systems, and the accuracy of their assessments can be variable depending on experience and training. Moreover, the potential for human error in image interpretation can lead to either false positives or false negatives, which may have serious implications in critical fields such as security and healthcare.

Another limitation is the cost and complexity of implementing X-ray inspection systems. High-quality X-ray equipment can be expensive to acquire and maintain, which can deter smaller organizations from adopting these technologies. Additionally, the setup and operation of these systems often require specialized training and ongoing support, further adding to the costs. Furthermore, regulatory compliance and safety protocols associated with handling X-ray equipment impose additional operational challenges, necessitating further investment in training and safety measures to protect personnel from exposure. As a result, while the benefits of X-ray inspection technologies are clear, addressing these challenges is essential for maximizing their effectiveness and ensuring safety in various applications.

Future Trends in X-Ray Inspection Systems and Their Impact

The landscape of X-ray inspection systems is poised for significant transformation, driven by advances in technology and a growing emphasis on safety and efficiency across various industries. According to a recent report by MarketsandMarkets, the global X-ray inspection equipment market is projected to reach USD 2.12 billion by 2026, showcasing a compound annual growth rate (CAGR) of 7.8% from 2021. This growth is largely attributed to increased adoption of automation in inspections, enhancing not only safety measures but also operational efficiency in sectors like manufacturing, healthcare, and security.

Future trends indicate a shift toward the integration of Artificial Intelligence (AI) and machine learning into X-ray systems, enabling real-time data analysis and improved image interpretation. A study by Grand View Research indicates that AI-driven X-ray systems can outperform traditional methods by reducing false positives by up to 30%, minimizing the risk of human error and increasing the speed of inspections. As these technologies evolve, they are expected to facilitate more precise inspections, significantly enhancing safety protocols in various applications.

Tip: When considering the implementation or upgrade of X-ray systems, evaluate the potential benefits of AI integration to optimize safety and operational efficiency. Additionally, staying informed about emerging technologies can provide a competitive advantage in ensuring compliance and enhancing overall performance.

As industries continue to embrace innovative practices, the impact of these advancements in X-ray inspection systems will be profound. Facilities adopting the latest technologies will not only bolster safety measures but also streamline operations, ultimately leading to improved productivity and cost savings.

Related Posts

-

How to Use Xray Inspection for Effective Quality Control in Manufacturing

-

Top 10 Benefits of Using X Ray Inspection Machines in Quality Control

-

2025 Top X-Ray Machines for Food Processing: Ensuring Safety and Quality

-

Why Metal Detectors Are Essential for Quality Control in the Pharmaceutical Industry

-

What are Food Inspection Systems and How Do They Ensure Safety?

-

2025 How to Utilize Xray Inspection Technology for Enhanced Quality Control in Manufacturing